In The Mix E-Newsletter- May / June 2020

Ask us about virtual trainings, presentations and webinars!

In This Issue

Circulate. SolarBee® Active Circulation For Raw Water Reservoirs

Control cyanobacteria and improve your water quality!

Lake Learning Videos & Other Helpful Materials

Quick and easy information to help you understand & improve your lake water quality.

New Video! What Are Disinfection By-Products In Drinking Water?

Welcome to our new Watercare 101 Presentation Series!

Mix Lift Station Wet Wells. Fight Wipes. Stop Clogs.

Sign up for the AP500 Wet Well Mixer "Try Before You Buy"

• Interested in a remote presentation or webinar? Contact us to set one up!

• Check out our Video Library for more educational videos and information!

Circulate. SolarBee® Active Circulation For Lakes

Make your raw water the best it can be.

SolarBee® SB Series mixers take advantage of the way water forms thin horizontal layers in all reservoirs. Utilizing solar power and highly efficient motor / mixing drive systems, the SolarBee® pulls in water at the desired depth from all corners of the basin providing effective mixing to a predetermined depth. SolarBees are designed to operate 24 hours per day on solar power, utilizing digital logic for power management, auto-reverse, and anti-jam features. They are a scalable solution for most applications where water quality improvement is desired.

Treat up to 35 acres per SolarBee® Lake Circulator!

Treat up to 35 acres per SolarBee® Lake Circulator!

There are two types of targeted circulation that can help resolve a host of water quality problems.

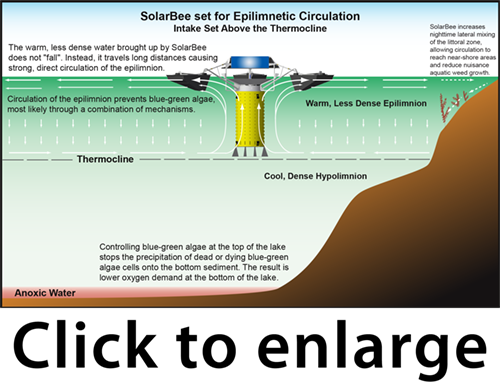

Epilimnetic Circulation

The circulator intake is set just above the thermocline or point of significant temperature stratification to circulate just the upper part of the water column.

The circulator intake is set just above the thermocline or point of significant temperature stratification to circulate just the upper part of the water column.

• Prevents and controls cyanobacteria (blue-green algae) blooms.

• Reduces taste and odor problems in drinking water reservoirs.

• Improves dissolved oxygen (DO) and pH levels throughout the circulation zone.

• Reduces invasive aquatic weeds & filamentous algae.

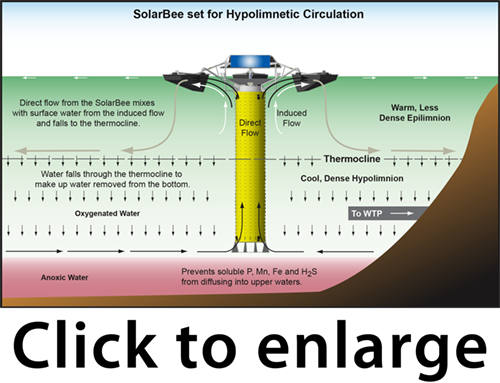

Hypolimnetic Circulation

The circulator intake is set deep in the reservoir below the thermocline to continuously bring up and expose bottom waters to the oxygen-rich epilimnion and atmosphere.

The circulator intake is set deep in the reservoir below the thermocline to continuously bring up and expose bottom waters to the oxygen-rich epilimnion and atmosphere.

• Oxidizes manganese (Mn) and iron (Fe)

• Helps to prevent fish kills.

• Continuously de-gasses H2S.

• Reduces methyl-mercury (Hg).

Contact us to learn more how we can help improve your water quality via active lake circulation!

Lake Learning Featured Videos

Part 1: How Does A SolarBee Circulate A Lake?

Learn the ABCs of SolarBee Lake Circulator flow creation and circulation patterns used for cyanobacteria (blue-green algae) control.

Part 2: How Does SolarBee Control Cyanobacteria (Blue-Green Algae) In A Lake?

Learn the four likely cyanobacteria (blue-green algae) control mechanisms utilized by SolarBee® Lake Circulators in lakes and raw water reservoirs in this quick and easy four-minute video.

What is an AerationPlus© Lake & Pond Circulator?

The AerationPlus© Lake & Pond Circulator is a perfect circulation solution for private consumers and public entities looking to implement an effective & affordable circulation strategy for water quality improvement.

Lake Learning Materials

Ixom Watercare has compiled a two valuable reference guides to help you better understand lake vocabulary, processes and treatment options in laymen's terms.

The "Lakes A To Z Help Guide" is just that, a quick and easy reference tool for all things involving lake water quality and treatment. Ixom Watercare's lake knowledge is not only based on study, but also on real-world, on-the-water field work. We think this guide will prove to be a useful resource for lake & pond stakeholders as they work to maintain and improve their water quality.

The "Lakes A To Z Help Guide" is just that, a quick and easy reference tool for all things involving lake water quality and treatment. Ixom Watercare's lake knowledge is not only based on study, but also on real-world, on-the-water field work. We think this guide will prove to be a useful resource for lake & pond stakeholders as they work to maintain and improve their water quality.

The "Seasonal Changes In Lakes Primer" will give you a very quick overview of lake behavior in the northern United States over the course of the four seasons. For lakes in the warmer, southern regions of the U.S. that don't experience winter ice over, the other three seasons spread out over more months to give these lakes a repeating cycle too.

The "Seasonal Changes In Lakes Primer" will give you a very quick overview of lake behavior in the northern United States over the course of the four seasons. For lakes in the warmer, southern regions of the U.S. that don't experience winter ice over, the other three seasons spread out over more months to give these lakes a repeating cycle too.

New Video! What are disfection by-products in drinking water?

Welcome to our new Watercare 101 Presentation Series!

Mix Lift Station Wet Wells. Fight Wipes. Stop Clogs

Sign up for the AP500 Wet Well Mixer "Try Before You Buy"

The AP500 is ideal for almost all types of liquids in municipal and industrial wastewater treatment tanks, basins & ponds, or as a backup mixer. shallow or deep - wherever mixing is needed.

Wipes clogging your pumps? Odor problems? Corrosion? Excessive grease?

Mixing keeps helps keep solids—such as wipes—in suspension as sheets instead of clumps and prevents lift station pumps from clogging. Mixing also helps reduce H2S odors and corrosion as well as grease buildup.

And it's easy. The AP500 shipped as a complete system including...

• the mixer,

• a quiet, long-life air unit,

• and the air hose

Need more information?

Give us a buzz at 866-437-8076 or

through our website!